Chariness + Professional + Precision testing equipment = Stable quality assurance

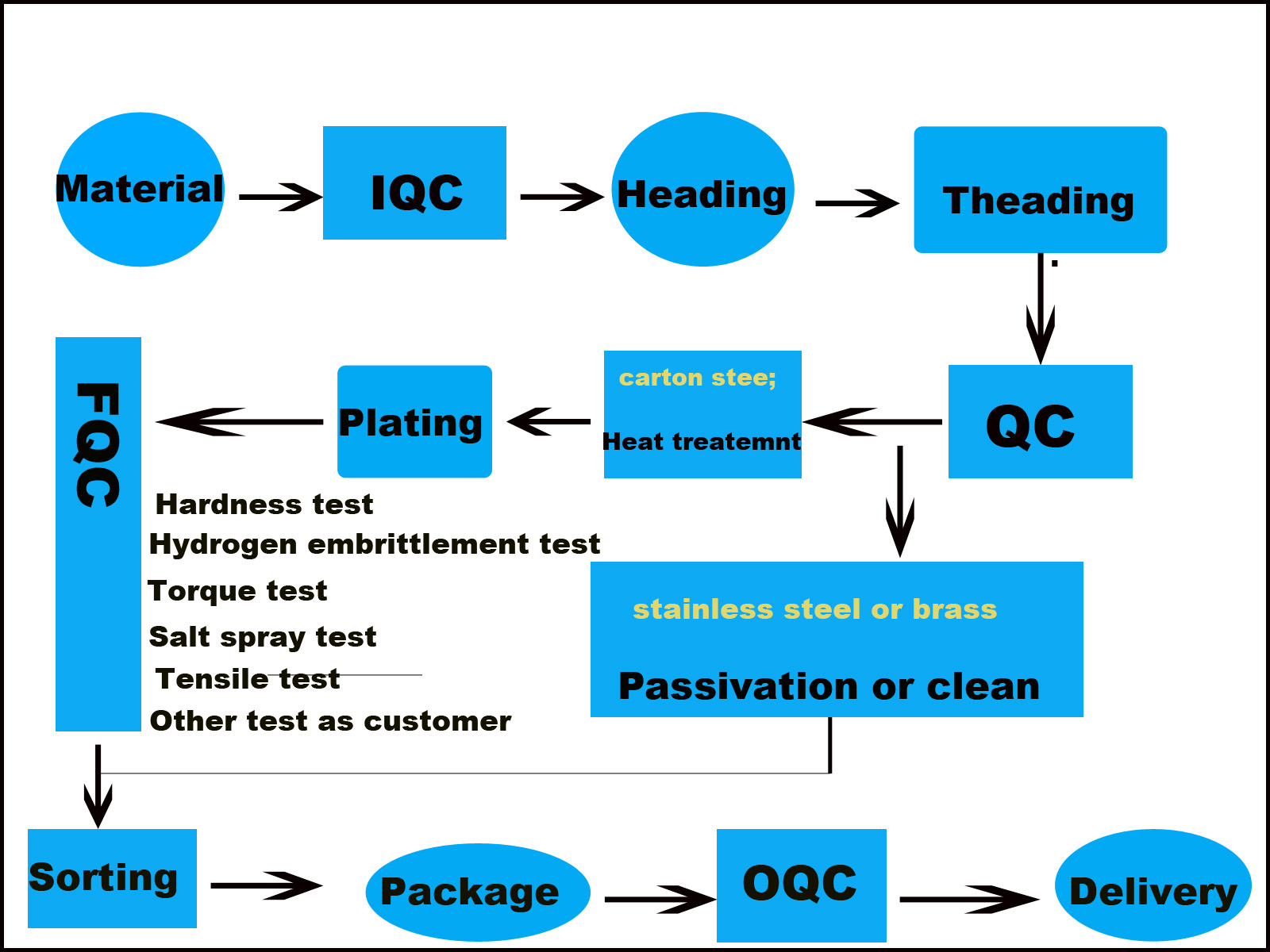

Yuhuang screw quality control process can be listed as follows:

In different process, we follow the different standard specification as following shown:

Material Criterion

- We are not accept any mix material

- Material package should accord with general criterion

- We are not accept the deformation steel

- Steel surface cannot be scratched

- Any corrosion is not acceptable

- Hardness standard will follow as client’s requirement

- All the wire diameter will follow the engineer drawing

Require inspection facilities:

|

|

| Micrometer | Hardness Test |

Manufacturing Criterion

The manufacturing process will focus on the head forming, thread forming, and cleaning. We won’t accept the screw products with any scratch, decentration, blocking, subsidence, bending, thread mix, dirty, oxidation, and so on.

Require inspection facilities:

|

|

|

| Micrometer | Projector | Go and No-go |

General Screw Test Criterion

Our screw test will accept the tolerance within ±0.1mm. Our minimum screw can reach up to ±0.03mm.

Screw Outgoing Quality Control Criterion

Screw – No scratch, decentration, blocking, subsidence, bending, thread mix, dirty, oxidation, and so on.

Nut – No rust, decentration, oxidation, damaged, and so on. We also accept the specific check as client’s requirement.

Flat Gasket/Spring Washer – No deformation, oxidation, washer opening, and so on.

Require inspection facilities:

|

|

|

| Micrometer | Projector | Go and No-go |

|

|

|

| Torsion | Plating Thickness | Salt Spray Test |

Salt Spray Test Criterion

All the salt spray tests by Yuhuang are strictly follow the GB641, GB12335,GB/T9798 1997 requirement. The salt spray test criterion can be listed as follows:

Blue Zinc – at least 24 hours salt spray test, nigrities area less than 10%

Black Zinc – at least 24 hours salt spray test, rust area less than 1%, plating fall off less than 20%, bubble area less than 5%

White Zinc – at least 24 hours salt spray test, no rust, nigrities area less than 10%

Electrophoresis – at least 24 hours salt spray test, no rust acceptable

Nickel Plating – at least 12 hours salt spray test, no rust, slushing oil should be volatility

Color-Zinc – at least 24 hours salt spray test, no rust

Black Plating – at least 12 hours salt spray test, no rust

Phosphating – at least 24 hours salt spray test, no rust

Yuhuang salt spray test environment

PH 6.5~7.2, brine strength 5±1%, daily volume of spray 1.0-2.0ML/8CM2/N, air pressure 1.00+/-0.1KGF/CM2, temperature 35+/-1°C, temperature in pressure area 47+/-1°C.

Torsion and Thickness Test

Thickness Criterion

| Level | Surface Hardness(HV) | Core Hardness (HV) | Carburized Layer Depth(mm) |

| #0(screw diameterφ≤2.0) | 410-490 | 250-330 | 0.03-0.10 |

| #1(screw diameter 2.0<φ<

3.0) |

430-530 | 250-350 | 0.04-0.10 |

| #2(screw diameterφ≥3.0) | 450-550 | 250-360 | 0.05-0.18 |

| Stainless Steel | Minimum HV 321 | Minimum HV 171 | – |

| Minimum HRC 32.3 | Minimum HRB 85 | – |

Torsion Criterion

JIS Torsion Criterion

| Diameter

Dentoform |

A dentoform | AB/B dentoform | M/S dentoform | ST/CT metal self tapping dentoform | BT/RT plastic self tapping trigonodont |

| M1.2 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| M1.4 | 1.4 | 1.4 | 1.4 | 1.5 | 1.4 |

| M1.6 | 2.4 | 2.4 | 2.4 | 2.5 | 2.4 |

| M1.7 | 2.4 | 2.5 | 2.5 | 2.6 | 2.5 |

| M2.0 | 4.3 | 4.3 | 4.3 | 4.5 | 4.3 |

| M2.3 | 6.0 | 6.4 | 7.0 | 7.8 | 6.4 |

| M2.5 | 8.8 | 8.8 | 9.4 | 9.8 | 9.0 |

| M2.6 | 9.8 | 9.8 | 9.8 | 10.8 | 10.0 |

| M3.0 | 15.0 | 16.0 | 16.0 | 18.0 | 16.0 |

| M3.5 | 24.0 | 26.0 | 26.0 | 28.0 | 25.0 |

| M4.0 | 35.0 | 36.0 | 36.0 | 37.0 | 35.0 |

ANSI Torsion Criterion

| Spec.

Dentoform |

A dentoform | AB/B dentoform | PT dentoform | ST dentoform | M dentoform |

| #2 | 4.6 | 4.6 | 4.6 | 6.9 | 5.8 |

| #3 | 10.4 | 10.4 | 10.4 | 11.5 | 10.4 |

| #4 | 14 | 15 | 15 | 17 | 15 |

| #5 | 21 | 21 | 21 | 23 | 21 |

| #6 | 28 | 28 | 28 | 31 | 26 |

| #7(5/32) | 34.5 | 34.5 | 34.5 | 36.8 | 33.4 |

| #8 | 45 | 45 | 45 | 54 | 48 |

| #10(3/16) | 55.2 | 64.4 | 64.4 | 85.1 | 64.4 |

Require inspection facilities:

|

|

| Hardness Test | Torsion |

We sample check with every order at least 10pcs for full test, 10pcs for surface hardness test, 5pcs for core test.